When severe winter weather recently swept across Ohio and much of the eastern United States, it put significant strain on the electric grid. As temperatures dropped, electricity demand surged and fuel systems tightened. It was a challenging period that once again showed what truly matters during extreme cold: a reliable, diverse power supply that performs under pressure.

Cardinal Power Plant

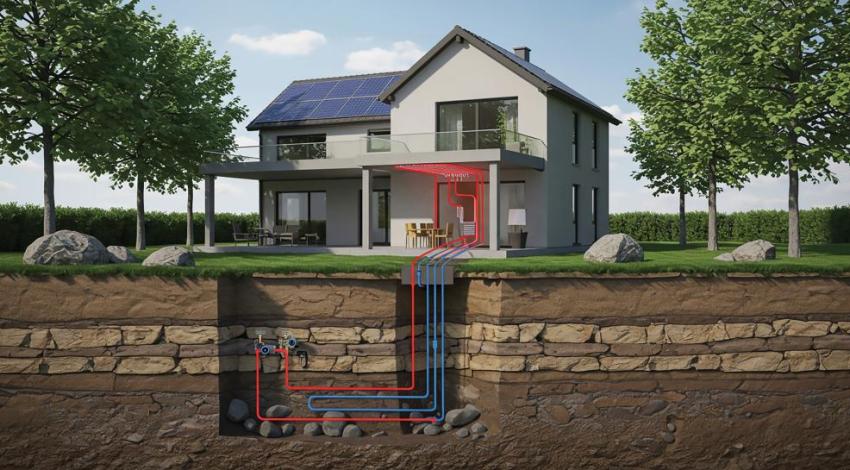

At about 4:30 a.m. one frigid Monday this past December, a signal went out from Columbus that temporarily switched off electric water heaters, furnaces, heat pumps, and geothermal systems in tens of thousands of electric cooperative members’ homes around the state.

Buckeye Power, the generation and transmission cooperative that provides the electricity Ohio’s co-ops distribute to their members, can reduce costs and ease strain on the grid by cycling those appliances off and on for short periods of time when the demand for power is at its highest. More than 100,000 co-op members in Ohio volunteer to participate in the program.

Last February, WKYC-TV in Cincinnati had a warning for its viewers: “Get ready, Ohio: Your energy bill will be higher this summer.”

If you watch, read, or listen to news outlets in Ohio, you’ve been bombarded for most of the past year about skyrocketing electricity rates. For most consumers, whether customers of an investor-owned utility or members of an electric cooperative, those stories likely were difficult to process.

The U.S.

“Buckeye Power has invested more than $1 billion in environmental controls over the past 20 years,” says Pat O’Loughlin, Buckeye’s president and CEO. “To put it in perspective, that’s over half of everything we’ve invested in the entire history of our company, and those investments have produced dramatic results in cleaner air, cleaner water, and significantly reduced solid waste such as ash.”

Electric-industry leaders nationwide are pushing back against the U.S. Environmental Protection Agency’s recently announced regulations that those leaders say are a threat to the reliability and affordability of electricity in the U.S.

One of the new rules would require Cardinal and other coal-fired plants to be 90% carbon-emission free by 2032 and points to carbon capture and sequestration — technology that does not and is not likely to exist at a scale that would be necessary — as a means to achieve it. Generating facilities unable to meet the demands would be forced to close.

The United States Environmental Protection Agency’s new rule on greenhouse gas emissions from power plants will, if implemented, have severe negative consequences not only for Ohio but for our entire nation.

The rule requires existing coal-fired power plants to nearly eliminate the carbon dioxide they emit by first capturing the carbon that’s produced when coal burns and then pumping it deep underground. The rule requires compliance by Jan. 1, 2032.

January is always a good time to take stock of things — to prepare for what’s ahead in the coming year — and often, your electric cooperative finds a long list of upcoming events and things to consider as we try to make sure we’re ready for whatever comes our way. Our list seems to be a little shorter this year, but that doesn’t mean we have less to do or less to worry about. We have some important long-term goals that we need to make progress on to ensure that we can continue to provide the reliable and affordable electric service that you’ve come to expect.

Electric power is a service that is simultaneously deeply appreciated and yet taken for granted.

Powering Ohio’s co-ops

“We all take electricity for granted, until you’re at your own house and you lose it, and then you say, ‘Where’s the power company?’” laughs Schunn, plant manager for the Cardinal Power Plant in Brilliant, a small town on the Ohio River in eastern Ohio. Cardinal’s three coal-burning units produce up to 1,800 megawatts of power at a given moment. It’s the main baseload generating plant for Buckeye Power.

When we think about the people keeping our lights on, most of us think of the lineworkers who build, maintain, and repair the power lines running through our communities. Behind the scenes, though, it takes another crew of dedicated men and women to keep that power flowing — and that’s something we can all appreciate as we sit in our air-conditioned homes during the hot and humid “dog days” of summer.