Ohio, believe it or not, is the largest wool-producing state east of the Mississippi River. Sheep farms here come in all sizes, from larger commercial operations to small boutique plots.

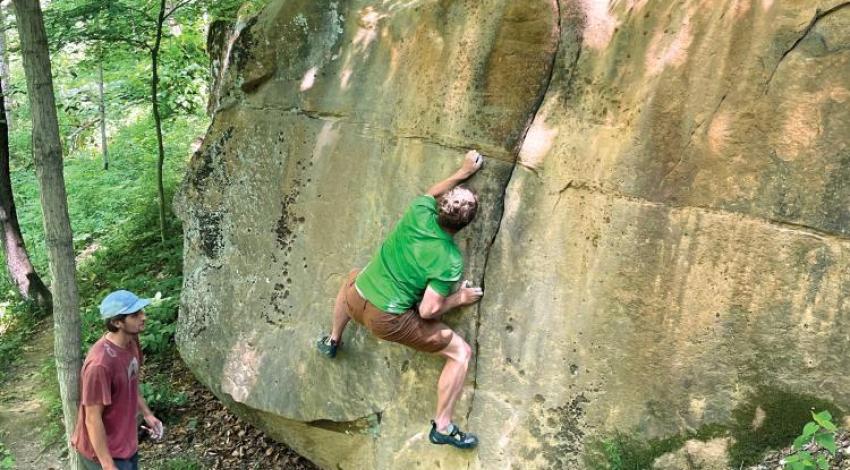

Rick Moore says seeing his sheep outside on a green pasture is “as close to heaven as it gets” (photo courtesy of Rick Moore).

Multigenerational

Rick Moore is the seventh generation in his family to raise sheep at Cottage Hill Farm near Cadiz in Harrison County. The farm began as a land grant signed by James Madison in 1816.

Moore’s son Steven and his father, Stanley — still active at 88 — farm with him. The foundation of Moore’s flock is 250 purebred Merino ewes. In alternating years, some are bred to purebred Merino rams and continue the line of high-quality wool production, while others are crossed with other breeds to produce lambs for meat.

“Quality always sells,” Moore says. “Merino wool that’s really white, not a lot of grease in it, with 3½- or 4-inch-long staple fibers, gets the high dollar.” The diameter, or micron, of the wool fibers also affects price — the smaller the diameter, the finer the wool. Wool from the Moores’ Merinos measures 15 or 16 microns, compared to 18 or 19 for coarser wool from other breeds of sheep.

The Moores’ farm follows an annual schedule. Ewes that don’t have lambs in a given year, along with the rams, are shorn each May by a professional shearer, and the fleeces are carefully stored in the barn hayloft. The Moores then sell their wool, by the pound, directly to textile mills.

Moore says the best part of raising sheep is “to see them outside on green grass in the spring. That’s got to be as close to heaven as it gets. We’re truly blessed.”

Rare breeds

Cheryl Dunlap’s sheep-raising and wool-producing business is called Old Orchard Romneys and Romeldales. It’s a small, specialized operation located in Lore City, where she’s a member of Guernsey-Muskingum Electric Cooperative. Dunlap says her family has raised sheep for as long as she can recall. “I remember being in the barn when I was a toddler, watching my grandfather and uncles shear sheep. I had sheep in 4-H, and my kids were in 4-H with sheep, too.”

After her children were finished with 4-H, however, she says the farm became empty and quiet, so she bought five ewe lambs to raise, intending to keep one and sell the others. She soon learned that all sheep are not created equal, and hers were difficult and unruly.

“A friend had Romney sheep. The ewes were so docile, so I gave my flock to a cousin and got a flock of Romneys,” she says.

Not long after, she added Romeldales, a rare breed whose status the Livestock Conservancy lists as “threatened.”

“It’s super hard to find [a Romeldale] not related to what you already have,” she says. “Their breeding pool is extremely small.”

Dunlap sells the fleeces her sheep produce exclusively to hand-spinners, who prefer the natural cream, gray, and tan shades produced by her Romneys and Romeldales. She says her fleeces are also preferred because they’re clean. Very clean.

Dunlap’s sheep wear blankets year-round. She bought a wringer washer just for their blankets, which she changes often.

That kind of effort helped Dunlap win the fleece championship at the Maryland Fleece and Wool Festival a few years ago — which put her on the radar of hand-spinners. One hand-spinner buys every fleece Dunlap has from her Border Leicester sheep.

“When I first started, I got $8 to $12 a pound for wool,” Dunlap says. “Now I get $18 to $30 a pound because my sheep wear blankets. The hand-spinners are willing to pay for clean, quality wool.”

Off to market

When it comes time to sell their wares, many farmers find their way to Mid-States Wool Growers Cooperative Association in Canal Winchester, where producers from 23 states sell their fleece. Mid-States is a member of South Central Power Company.

“We sell to textile mills and to exporters who sell to textile mills in other countries,” says Dave Rowe, Mid-States’ general manager.

The cooperative operates year-round. When wool arrives, it is inspected and graded, then stored in the warehouse until either an order arrives or Rowe calls a buyer and sells it directly. Rowe says that for a typical order, “we’re going to be moving by shipping containers or semis, in 43,000-pound lots. It has to be a large quantity that makes the freight [cost] worth it.”